What is a Digital Twin?

ADVANCED IMAGING ALGORITHM FOR THE DIGITAL MANAGEMENT OF BUILDINGS AND CONSTRUCTION SITES

What if we could have instant access to all the information about a construction site, down to smallest details about every person, tool, and bolt?

What if we could always be sure about the final measurements of a beam or that soil volumes in the cuts are close to those of the fills? What if we could always track how fast the supply of materials runs out, and re-order supplies automatically?

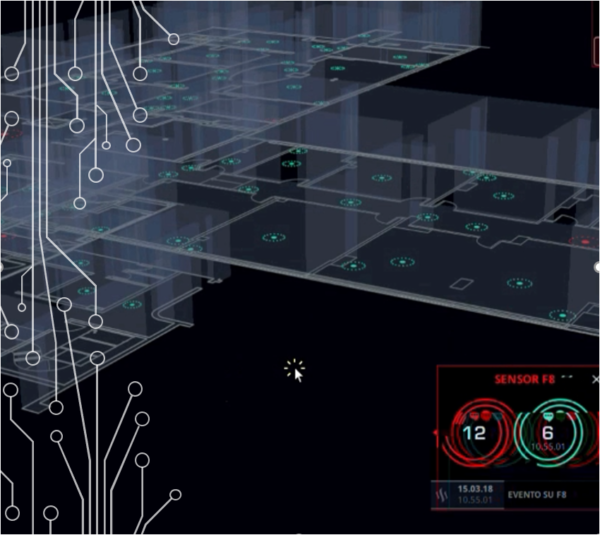

Konectcity Platform is essentially a link between a real world object and its digital representation that is continuously using data from the sensors. All data comes from sensors located on a physical object ( HVAC, thermostats, alarms, cameras, database; this data is used to establish the representation of an existing object in our VR world so that, from one single screen, we interact with the 3d virtualization of every connected asset wherever located in the globe.

Using KonectCity means always having access to as-built and as-designed models, which are constantly synced in real-time

Predictive analysis based on algorithm and machine learning

We can use the model predictive control approach and make decisions based on forward simulation, beginning with the current state of the building. So we can always analyze different paths of actions and estimate their probabilities and corresponding cost functions in order to select the most optimal decision (or adjustment) for what we should do next.

Our AI automated progress monitoring verifies that the completed work is consistent with plans and specifications. A physical site observation is needed in order to verify the reported percentage of work done and determine the stage of the project.

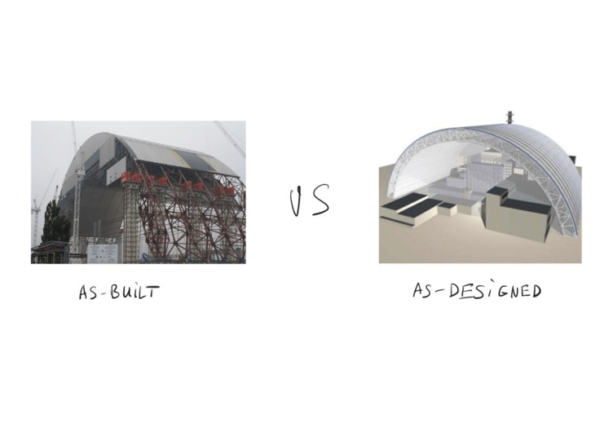

By reconstructing an as-built state of a building or structure we can compare it with an as-planned execution in BIM and take corresponding actions to correct any deviations. This is usually done by reconstructing geometry of a building and registering it to the model coordinate systems, which is later compared to an as-planned model on a shape and object level.

Often data for progress monitoring is collected through the field personnel and can be hugely subjective. For example, the reported percentage of work done can be faster in the beginning and much slower close to the end of the project.

People tend to be initially more optimistic about their progress and the time needed to finish the job.

Hence, having automated means of data collection and comparison means that the resulting model to as-designed BIM models is less liable to human error. Digital twins solve the common construction process problems helping saving time, overrunning costs and resources greatly benefiting the bottom line.

AS BUILT VS AS DESIGNED MODELS

With a real-time digital twins, it is possible to track changes in an as-built model daily and hourly. Early detection of any discrepancies can lead to a detailed analysis of historical modeling data, which adds an additional layer of information for any further decision making processes.

Project managers can track and reconstruct steps that led to errors adjusting work schedules accordingly in order to prevent any similar mistakes from occurring.

They can also detect under-performers and fix the cause of the problem planning the necessary changes to the budget and timescale of the whole project. According to the Construction Industry Institute, about 25% of productive time is wasted on unnecessary movement and handling of materials. Our technology provides automatic resource allocation monitoring and waste tracking, allowing for a predictive and lean approach to resource management. Companies would avoid over-allocation dynamically predicting resource requirements on construction sites, thus avoiding the need to move resources over long distances greatly improving time management.

The construction industry is one of the most dangerous sectors in the world.

Early notification, using our advanced AI combined with video cameras and mobile devices combines an extensive safety net letting construction managers know when a field worker is located in dangerous proximity to working equipment and sending a notification about nearby danger to a worker’s wearable device.

The real-time site virtual reconstruction allows companies to track people and hazardous places so as to prevent inappropriate behavior, usage of unsafe materials, and activities in hazardous zones.

Optimization

Equipment utilization is an important metric that construction firms always want to maximize. Unused machines should be released earlier to the pool so others can use them on other sites where they are needed. With advanced imaging and automatic tracking, it is possible to know how many times each piece of machinery has been used, at what part of the construction site, and on what type of the job.

Some countries impose tough regulations on how to monitor people presence on a construction site. This includes having a digital record of all personnel and their location within the site, so that this information could be used by rescue teams in case of emergency. This monitoring is another digital plug in offered by our platform.

Data processing and analytics

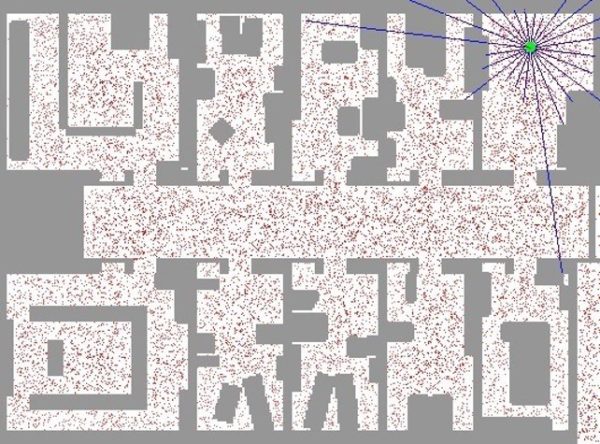

UAV are habitually used to collect laser dots referral points combining imaging cameras and sensors to build augmented reality images. A high rate of generated data demands an even higher rate of data processing and fully-automated pipelines, from data capturing and analysis to knowledge and decisions. Our geospatial engine processes high volumes of data for all layers and connected assets always offering real time information with a precise location and positioning on map offering a VR visualization on screen. Our system combines the most advanced photogrammetry algorithms combined with Structure from motion acquisition ( drones and cameras ) . These elements combined offer denser 3D representations that are more accurate in measurements when compared to any other method.

LOCALIZATION